Laser Engraving Systems

What are LASERS?

“LASER” is an acronym for Light Amplification by Stimulated Emission of Radiation. The radiation in this case is a wavelength of light and that light is transferred into a coherent monochromatic beam of light energy. Think of the beam of light as one wavelength of light intensely bounced back and forth between a source and then shot out in either a continuous or pulsed wave. We isolate the wavelengths by shooting the beam of light through different mediums.

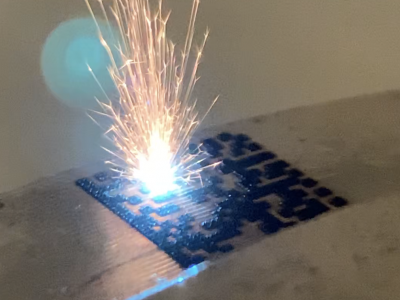

These mediums produce common wavelengths, such as 355nm (UV), 1064nm (Fiber), and 10,600 (CO2). Different wavelengths are absorbed by different materials. Each laser has a laser source that allows light to pass through it amplifying the effect. The photons are then bombarded onto the surface of the product where they burn/etch the image. LASERS are considered permanent and are an excellent way to quickly apply an image that is counterfeit resistant.

parts of a laser

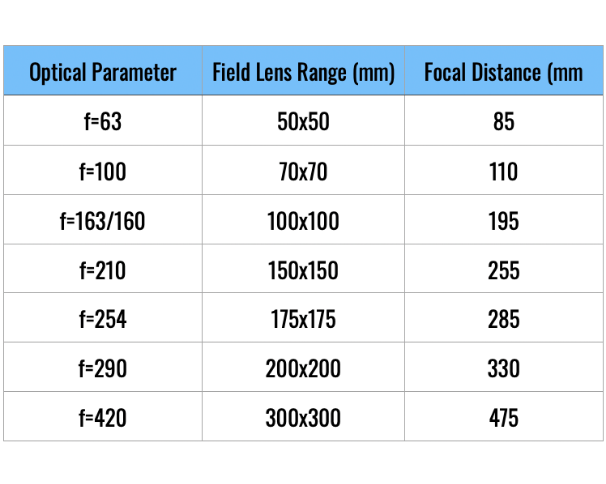

Three of the critical components of the laser are the laser source, the galvanometer (also called a galvo), and the lens. The source builds the energy and then shoots the energy into the galvanometer. The galvanometer redirects this energy through a series of rotating mirrors onto the part through the lens. To the left we can see the power supply for the galvo along with the red light generator. The red light generator allows a separate laser image to be cast onto the part before the part is marked to insure the mark is exactly where the operator wants it.

On the right is an image of the galvo with the lens removed and the laser moving the galvanometer’s mirrors quickly in rapid succession over the part.

Focus Matters

Different Wavelengths for Different Substrates

Materials absorb different wavelengths at different rates. This means one source (or one laser type) could mark one substrate but might not mark another. For example, clear substrates and ceramics usually do not react to fiber lasers but usually mark easily with UV lasers.

Software Equals Flexibility

Our easy-to-use software is based on EZCAD which allows users to import graphics, create shapes, write words, and adjust text size and font to create dynamic imaging and so much more. This means images can change on-the-fly. All of our laser systems come pre-loaded with the ability to mark bar codes, QR codes, micro-QR Codes, automatically count items, time stamp, increase serial numbers, and more.

Want to place a QR code directed to a specific website? It is easy with software that does the heavy lifting for you. Just type and go.

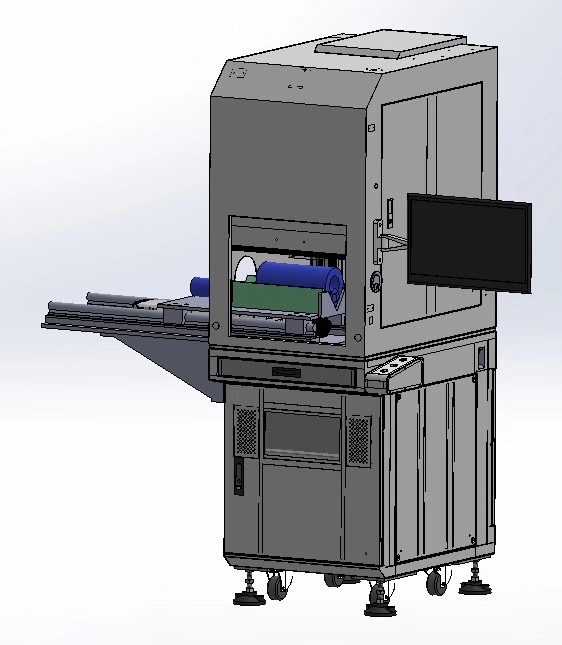

3D Capabilities and Rotational Printing

Round parts add a degree of difficulty when printing due to the Z-axis (height) changing. There are two ways to combat this. Using a 3D laser will allow a 90-degree portion of the round part to be printed on without rotating it. Our software provides rotational printing capabilities straight out of the box. Hook up a chuck adjustable rotary to allow automated part rotation for easy rotational printing.

Safety

Laser safety is essential. Improper use can result in damage to operator skin and eyes. Marking lasers are all classified as Class 4 lasers, which is the highest classification of lasers, and can cause devastating eye damage, significant skin damage, and ignite substrates.

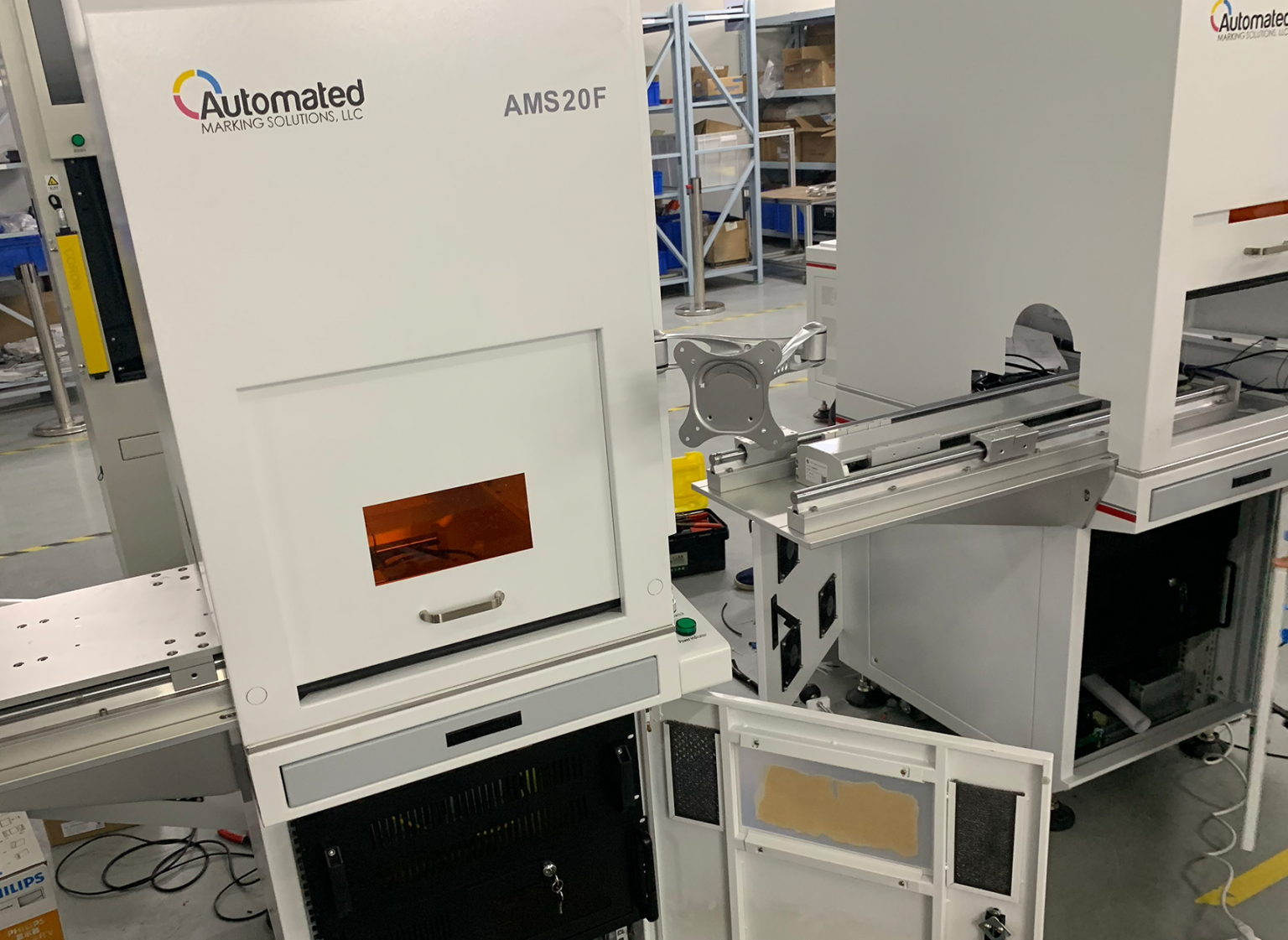

Automark lasers can be manufactured with FDA certified enclosures to insure a Class 4 laser is reduced to Class 1, which is the safest type of laser possible. It is important to discuss your safety concerns with your Automark representative prior to purchasing.

Need Something Custom?

Have a special project or need special considerations? We have you covered. Whether it is robotic integration, like the machines shown here, or special fixturing, we can build and assemble a laser system to fully accommodate your group’s requirements. We begin by learning about the integration of the product and then build it, virtually, for your approval before we have it built, physically. The result?

A one-of-a-kind solution specially designed for your unique application. The cost? The prices of these custom systems are very comparable with standard models. Contact us today to learn how we can help your group.