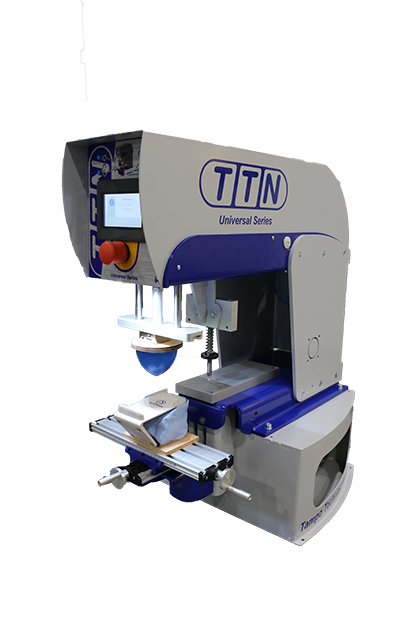

The Universal Series

Industry Leading Pad Printing Machinery

Redesigned for

A New Interface

Our new interface is designed and programmed in-house by TTN. This touchscreen is intuitive with lightning-fast responses. Its interface offers the following:

- Native 7 Language Support (English, Spanish, French, Italian, German, Dutch, and Portuguese) (included), with the ability to easily add more languages as needed in the future

- Part Counter (programming included)

- Know your true output with our Production-Per-Hour Counter

- Double-Print Capability for Dark Substrates

- Optional Tape Cleaner Function with Automatic Settings

- Simple to use interface with items greyed out that are not offered in that stage of the menu

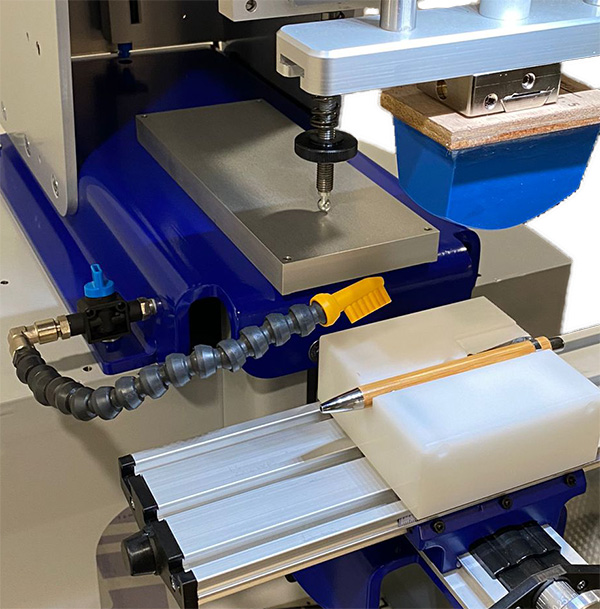

Keep That Pad Clean

The built-in optional tape cleaner is the perfect accessory to keep your printing perfect, while maintaining output and high productivity. Operators will appreciate this feature as the function is integrated into the control panel and can be easily initiated manually or can be programmed after a set number of cycles.

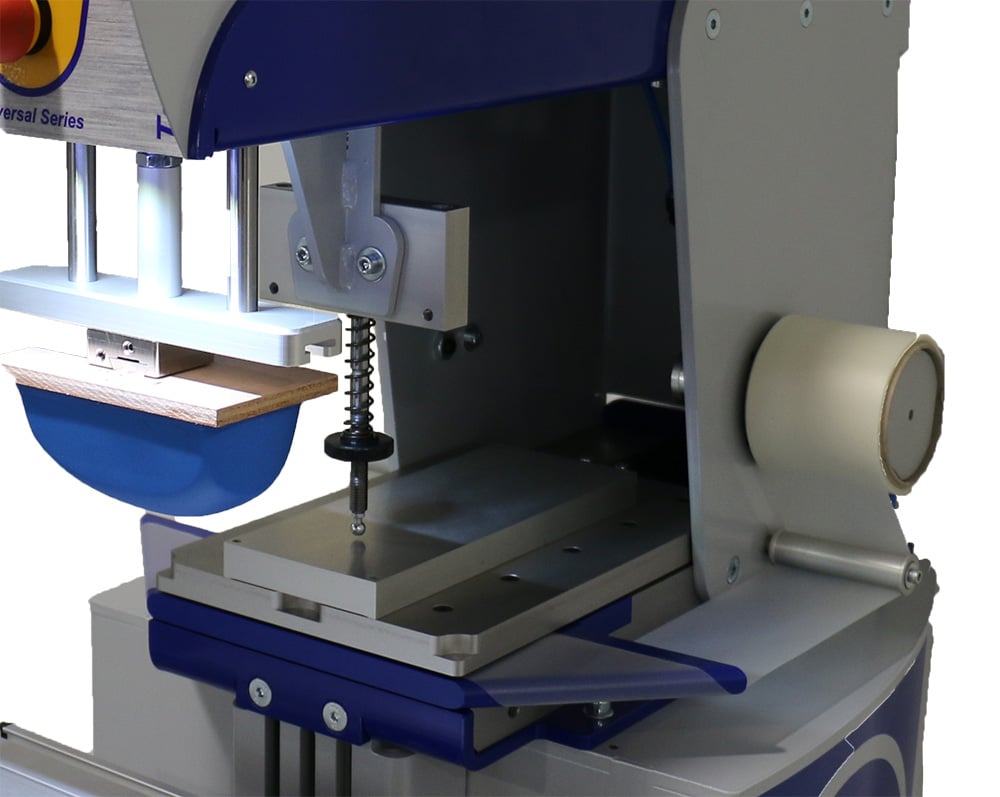

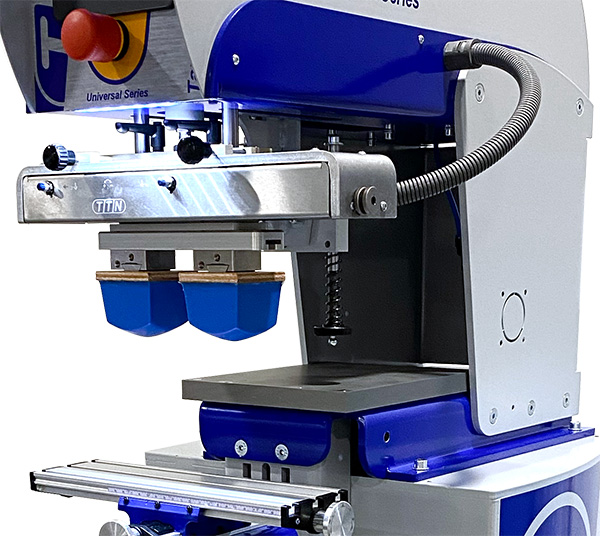

A Magnetic Attraction

Throw away clamps, screws, and holders. The world’s first magnetic cliché holder on an entry level pad printer. This allows operators to switch images in seconds. With the ability to quickly rotate the baseplate 180°, it can alternate between images in seconds whether on the same or a new plate.

Integrated Dryer

The new optional integrated pad and part dryer allows quick flow control including on/off operation. It can easily be moved out of the way or detached as needed. It can also greatly assist in preparing ink on the pad for printing items like glassware, where additional ink tackiness is desired.

Increased Durability

The contrasting blue and grey surfaces of the New Universal Series are powder coated to insure increased durability against cleaners and thinners, allowing your New Universal to stay cleaner longer and last longer than any other entry level machine in the market today.

Cleanroom Compliant for Medical Pad Printing

Our new Universal Series Pad Printer can be cleanroom compliant right out of the box for the perfect solution in medical applications.

All steel surfaces are powder coated

All aluminum parts are anodized

Easily upgrades to pads with a metal base making the entire machine cleanroom compliant

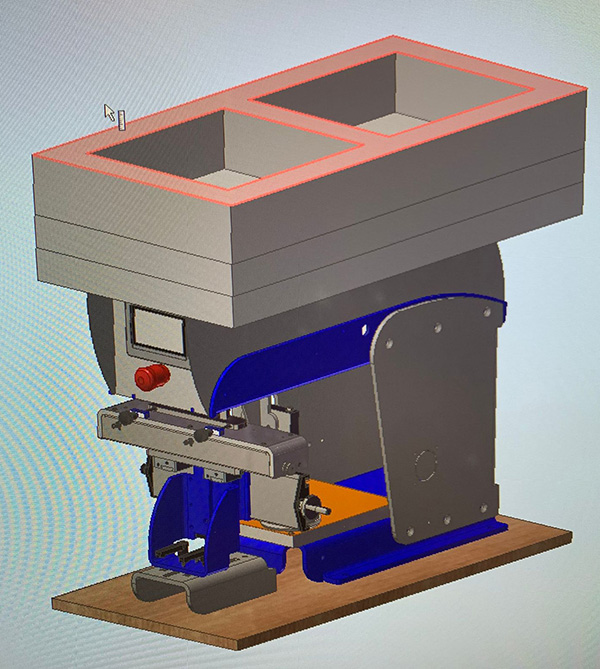

This is a great companion to our new Universal Series pad printers and offers hidden storage that is the perfect height for ink cans and owner’s manuals. This pedestal attaches to a table, which allows our TTN pad printers to easily attach.

This is perfect for mounting our Universal Series pad printers but can easily accommodate our entire line of TTN pad printers, with the ability to level the feet and plenty of easily accessible storage.

This one offers a much larger XY table with the ability to lower the table further than adjustments on other pedestals. This allows incorporation of additional fixtures, like the XY Fixture with Rotational Adjustment (shown above) for quick micro-adjustments.

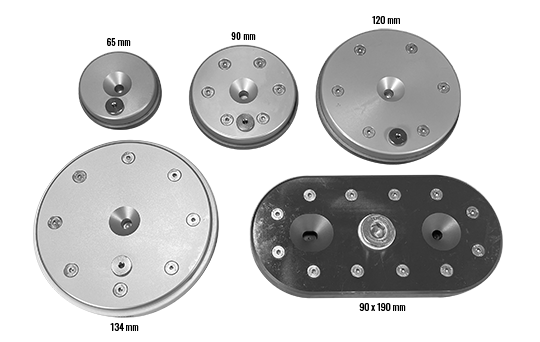

Quick Change Ink Cups

Our new Universal Series machines have quick change ink cups. No longer will you be locked into one ink cup size. The new Universal Series quickly allows image sizes to be changed in seconds. This means a Universal 90, with an ink cup of 90 mm, can use the 134 mm ink cup straight out of the box. Our 2-color Universal 200 series can even print with the larger 90×190 mm oval ink cup for an even larger image size.

We even redesigned your initial impression of our shipment interior, now ensuring low transport costs, while keeping your machine safe and sound!